6082

6082 Aluminium: High-Strength Alloy for Industrial Applications

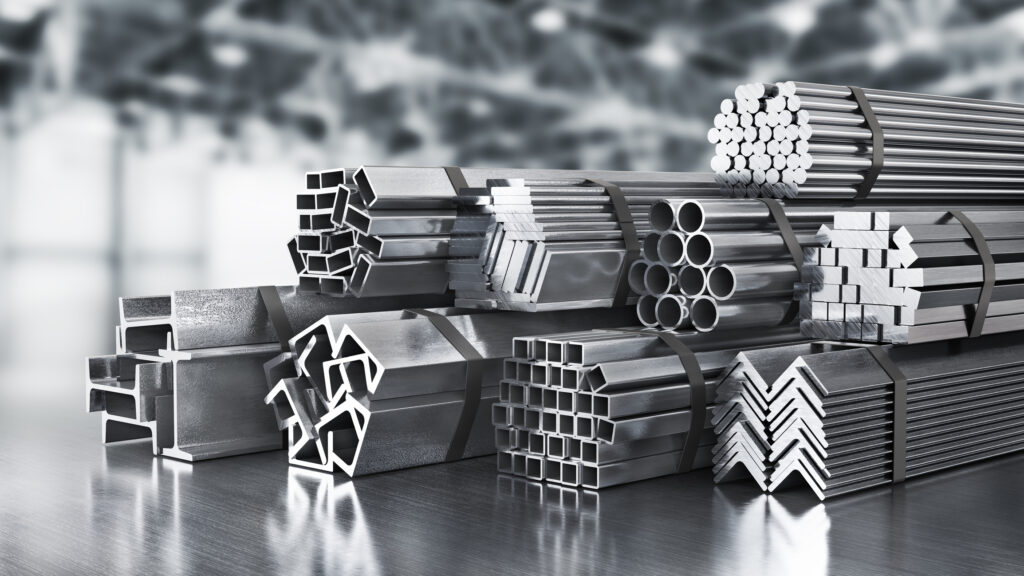

6082 aluminium is a high-performance, medium-strength alloy widely used in industrial applications such as machinery frames, tooling bases, and conveyor systems. Known for its superior strength and corrosion resistance, 6082 aluminium is the ideal material for structural components that require reliable performance. Russian Metals offers certified supply of 6082 aluminium with rapid delivery across India, catering to the needs of industries that demand precision, strength, and durability.

It is widely used in structural applications that require a combination of high strength, good corrosion resistance, excellent weldability, and machinability. Among all 6000-series alloys, 6082 has the highest strength, making it ideal for load-bearing and structural components in engineering, transport, and marine industries.

Overview of 6082 Aluminium Alloy

6082 Aluminium (also known as HE30 in the British system or AlSi1MgMn) is a medium-strength aluminium–magnesium–silicon alloy belonging to the 6000 series.

It is widely used in structural applications that require a combination of high strength, good corrosion resistance, excellent weldability, and machinability.

Among all 6000-series alloys, 6082 has the highest strength, making it ideal for load-bearing and structural components in engineering, transport, and marine industries.

Chemical Composition of 6082 Aluminium Alloy

| Element | Percentage (%) |

|---|---|

| Aluminium (Al) | Remainder |

| Silicon (Si) | 0.7 – 1.3 |

| Magnesium (Mg) | 0.6 – 1.2 |

| Manganese (Mn) | 0.4 – 1.0 |

| Iron (Fe) | ≤ 0.50 |

| Copper (Cu) | ≤ 0.10 |

| Chromium (Cr) | ≤ 0.25 |

| Zinc (Zn) | ≤ 0.20 |

| Titanium (Ti) | ≤ 0.10 |

| Others (each) | ≤ 0.05 |

The presence of silicon and magnesium enables precipitation hardening (heat treatment), while manganese refines the grain structure for improved strength and toughness.

Mechanical Properties of 6082 Aluminium Alloy

| Property | Typical Value |

|---|---|

| Ultimate Tensile Strength | 290 – 340 MPa |

| Yield Strength (0.2%) | 240 – 280 MPa |

| Elongation | 8 – 12 % |

| Brinell Hardness (HB) | 95 – 100 |

| Modulus of Elasticity | 70 GPa |

| Density | 2.70 g/cm³ |

Physical Properties of 6082 Aluminium Alloy

| Property | Value |

|---|---|

| Melting Point | 555 – 650 °C |

| Thermal Conductivity | 170 – 180 W/m·K |

| Electrical Conductivity | ~38% IACS |

| Coefficient of Thermal Expansion | 24 µm/m·K |

Applications of 6082 Aluminium

Machinery Frames:6082 aluminium is ideal for heavy-duty machinery frames due to its high strength and resistance to wear.

Tooling Bases:The alloy’s strength and excellent machinability make it a great choice for tooling bases in the manufacturing industry.

Conveyor Systems:Its durability and corrosion resistance make 6082 aluminium perfect for conveyor systems used in various industrial sectors.

Structural Components:Used in bridges, cranes, trusses, and other high-stress applications.

Applications of 6082 Aluminium in Industrial Engineering

Bridges and Cranes:Due to its high strength and resistance to corrosion, 6082 aluminium is used in heavy-duty applications such as bridges, cranes, and transportation systems.

Construction Projects:It is commonly used for construction frameworks and building exteriors that need to withstand stress and environmental exposure.

Transport and Aerospace:6082 aluminium is utilized in aircraft components, train frames, and marine applications due to its high strength and ability to perform well under stress.

Why Choose Aluminium 6082 T6?

The T6 temper of 6082 aluminium offers the best combination ofstrength andmachinability, making it ideal for applications that require high-performance materials.

Its excellent mechanical properties and corrosion resistance make it a preferred choice inmachinery,transportation, andindustrial systems, where reliability and long-term durability are essential.

Contact Us for 6082 Aluminum Orders

For more information or to place an order, contact Russian Metals today. We specialize in providing the best quality GOST 6082 aluminum at competitive prices for industrial, defense, and aerospace applications.

6082 France Aluminium alloy: Equivalent Grades for Russia, Ukraine, Belarus, Kazakhstan...