AMG6 (амг6)

AMG6 Aluminum Alloy: Superior Corrosion Resistance for Industrial Applications

AMG6 Aluminium is a high-strength aluminum–magnesium alloy (Al-Mg system) designed for applications that require exceptional corrosion resistance, toughness, and lightweight performance. Known for its outstanding mechanical strength combined with excellent weldability, AMG6 Aluminium is one of the most reliable alloys used across marine, aerospace, automotive, and structural engineering industries. This alloy is especially resistant to seawater and atmospheric corrosion, making it ideal for parts exposed to moisture, salt, and vibration. Compared to other magnesium-based aluminum alloys like AMG3 or AMG6, AMG6 Aluminium provides higher tensile strength while maintaining good formability.

What is AMG6 Aluminum?

AMG6 Aluminium is a magnesium alloy from the 5xxx series, known for its high strength and excellent corrosion resistance. This alloy is widely used in industries requiring materials that must withstand harsh conditions, such as chemical processing and marine environments.

- • High corrosion and seawater resistance

- • Strong yet lightweight (ideal for load-bearing components)

- • Excellent weldability and formability

- • Retains strength under moderate temperatures

- • Long-term durability with minimal maintenance

- • Non-magnetic, lightweight, and easily formable

- • High fatigue strength under cyclic stress

- • Stable mechanical properties across temperature variations

Characteristics for grade АMg6 (АМг6)

| Grade : | АМg6 (АМг6) (1560) |

| Classification : | Aluminium wrought alloys |

| Equivalent grades: | Is absent |

Chemical composition in % for grade АMg6 (АМг6)

| Fe | Si | Mn | Ti | Al | Cu | Be | Mg | Zn | Impurity |

|---|---|---|---|---|---|---|---|---|---|

| max 0.4 | max 0.4 | 0.5 - 0.8 | 0.02 - 0.1 | 91.1 - 93.68 | max 0.1 | 0.0002 - 0.005 | 5.8 - 6.8 | other, each 0.05; all 0.1 |

Mechanical properties under T=20°C for grade АMg6 (АМг6)

| Mechanical properties under T=20°C for grade AMg6 (AMr6) | ||||||||

|---|---|---|---|---|---|---|---|---|

| Assortment | Dimension (mm) | Direct. | σB (MPa) | σT (MPa) | δ (%) | ψ (%) | KCU (kJ/m²) | Heat treatment |

| Pipe, GOST 18482-79 | - | - | 255 | 110 | 15 | - | - | - |

| Bar, GOST 21488-97 | - | - | 245-265 | 110-120 | 10-15 | - | - | - |

| Band, GOST 13726-97 | - | - | 275 | 130 | 12-15 | - | - | - |

| Profile, GOST 8617-81 | - | - | 255 | 175 | 15 | - | - | - |

| Plate , GOST 17232-99 | - | - | 255-265 | 110-120 | 12-13 | - | - | - |

| Brinell hardness for АMg6 (АМг6) | HB 10 -1 = 65 MPa |

| Brinell hardness for AMg2 (AMr2), HB 10 -1 = 45 MPa |

| Brinell hardness for AMg2 (AMr2) (cold-worked), HB 10 -1 = 60 MPa |

| Weldability: without limitations. |

Physical properties for grade АMg6 (АМг6)

| T | E 10⁵ | α 10⁶ | λ | ρ | C | R 10⁹ |

|---|---|---|---|---|---|---|

| Grade | MPa | 1/Grade | Watt/(m·Grade) | kg/m³ | J/(kg·Grade) | Ohm·m |

| 20 | 2660 | 49.6 | ||||

| 100 | 126 | 922 |

Equivalent steels for grade AMg6 (AMr6)

Warning! Indicated both exact and nearest equivalents.

| USA | Germany | Japan |

|---|---|---|

| - | DIN, WNr | JIS |

| AA5056 | 3.3555 AlMg5 | 5056 |

Key Benefits of AMG6 Aluminum

Corrosion Resistance: AMG6 is highly resistant to corrosion, especially in marine and chemical environments, making it perfect for marine vessels, chemical tanks, and piping systems.

Superior Strength: AMG6 is stronger than most other aluminum alloys, making it suitable for structural components that demand high mechanical strength.

Good Weldability: This alloy is suitable for all types of welding and offers easy machining for industrial applications requiring high-precision parts.

AMG6 Aluminum Industrial Uses

AMG6 aluminum is widely used across various industrial sectors for its strength, corrosion resistance, and easy machinability.

AMG6 Aluminum in Chemical Equipment

AMG6’s resistance to corrosion and high strength-to-weight ratio make it a top choice for chemical equipment such as pipes, tanks, and reaction vessels. Its excellent machinability supports complex shapes in chemical processing plants.

AMG6 Aluminum for Industrial Applications

In industries such as automotive, aerospace, and shipbuilding, AMG6 is used in structural components that require high strength and resistance to harsh conditions. AMG6 aluminum rods and pipes are also used where lightweight durability is critical.

AMG6 Aluminum Machining and Fabrication

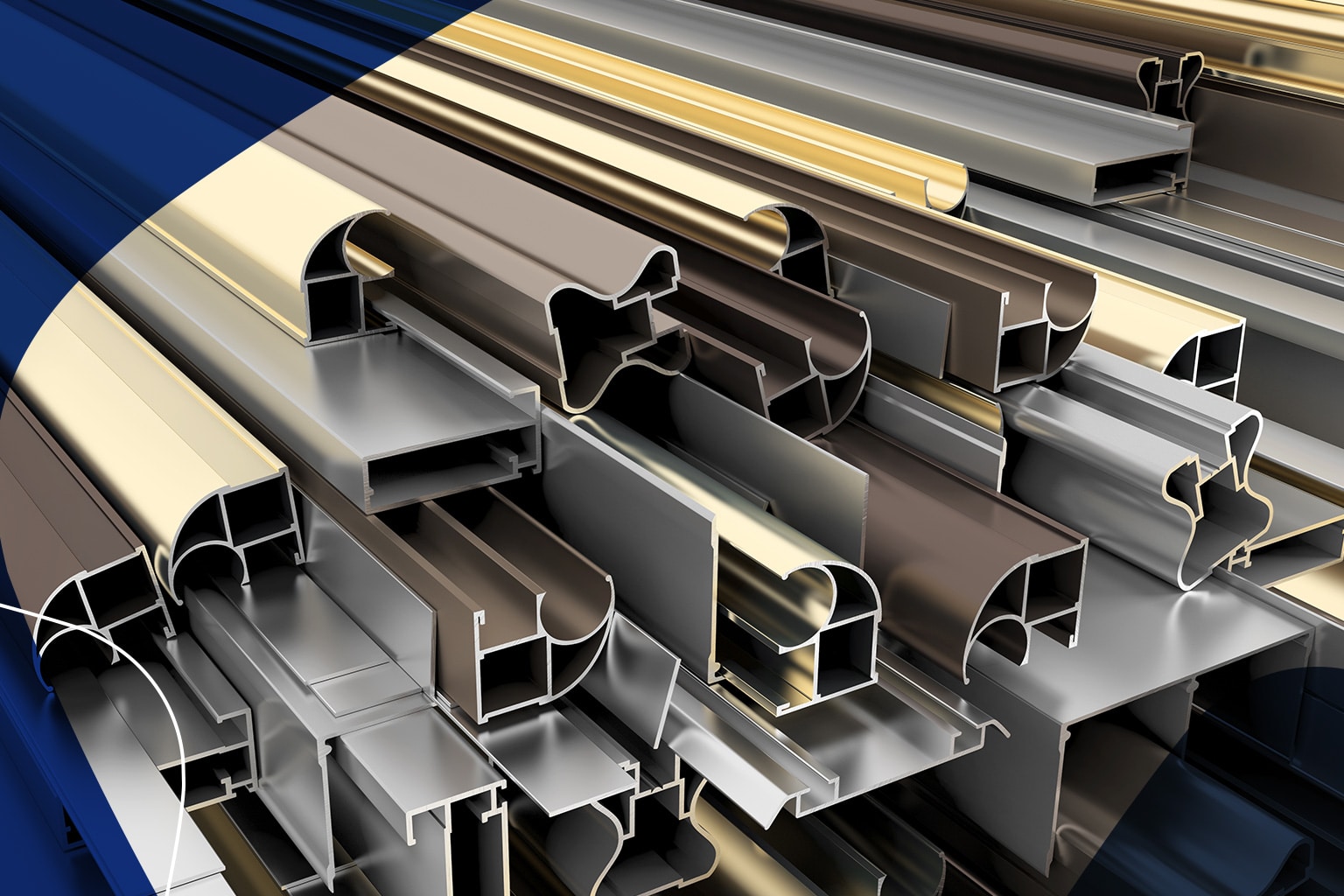

Russian Metals offers AMG6 aluminum machining services, delivering precisely crafted components, including rods, pipes, plates, and extrusions, to the highest industrial standards.

Why Choose Russian Metals for AMG6 Aluminum?

High-Quality Standards: AMG6 aluminum that meets the highest standards for corrosion resistance and strength.

Comprehensive Machining Services: Precision machining for rods and pipes to meet your exact specs.

Exporter of AMG6 Products: Global export with quick delivery and strict QA.

Types of delivery of grade AMg6 (AMr6)

B51 - Non-ferrous metals, including rare metals, and their alloys

B52 - Graded and shaped rolling

B53 - Sheets and Strips

B54 - Ribbons

B55 - Bars

B64 - Pipes of non-ferrous metals and alloys

Mechanical properties :

σB - Tensile strength [MPa]

σT - Yield stress [MPa]

δ5 - Specific elongation at fracture [%]

ψ - Reduction of area [%]

KCU - Impact strength [kJ/m²]

HB - Brinell hardness [MPa]

Physical properties :

T - Test temperature [Grade]

E - Young modulus [MPa]

α - Coefficient of linear expansion (20° - T) [1/Grade]

λ - Thermal (heat) condition coefficient [Watt/(m·Grade)]

ρ - Density [kg/m³]

C - Specific heat (range 20° - T) [J/(kg·Grade)]

R - Electrical resistance [Ohm·m]

Contact Us for AMG6 Aluminum Orders

For more information or to place an order, contact Russian Metals today. We specialize in providing the best quality GOST AMG6 aluminum at competitive prices for industrial, defense, and aerospace applications.