BT5-1 (БТ5-1)

BT5-1 Titanium Alloy for Aerospace and Industrial Applications

BT5-1 Titanium, also known as Ti-5Al-2.5Sn, is a high-strength titanium alloy that combines exceptional mechanical properties with excellent resistance to corrosion, making it suitable for a wide range of demanding applications. This alloy consists of 90% titanium, with 5% aluminum and 2.5% tin, offering a balanced mix of strength, toughness, and light weight. One of the key features of BT5-1 titanium is its outstanding strength-to-weight ratio, which makes it ideal for applications where reducing weight without compromising structural integrity is essential. This unique property is especially beneficial in aerospace and automotive industries, where weight reduction plays a critical role in performance and fuel efficiency.

Overview of BT5-1 Titanium Alloy

BT5-1, also known as VT5-1 (Russian: ВТ5-1), is a medium-strength α+β titanium alloy primarily used in aerospace, marine, and chemical processing applications. It is characterized by its balance of strength, ductility, and excellent corrosion resistance, making it suitable for components exposed to elevated temperatures and aggressive environments.

High Strength-to-Weight Ratio: Suitable for weight-sensitive applications.

Good Corrosion Resistance: Performs well in marine and chemical environments.

Excellent Weldability and Formability: Facilitates complex shapes and assemblies.

Biocompatibility: Suitable for medical applications.

Characteristics of the material BT5-1

| Grade : | BT5 |

| Classification : | Titanium wrought alloy |

| Application: | welded parts operating at temperatures from -253 to 400°C; good corrosion resistance; structure class α |

| Foreign analogues: | Known |

Why Choose BT5-1 Titanium for Aerospace and Industrial Machinery?

BT5-1 titanium alloy is known for its superior mechanical properties and resistance to extreme conditions. It is often used in aerospace components such as turbine engine casings, rings, and other high-performance parts that require both strength and durability. Here's why it stands out:

High Strength

Provides excellent tensile and yield strength at elevated temperatures, ideal for aerospace structures.

Corrosion Resistance

Withstands oxidation and corrosion up to 1200°F (649°C), making it suitable for chemical processing and other industries.

Creep Resistance

It maintains its integrity under long-term stress, making it perfect for turbine engines and other high-stress components.

Chemical composition in % of BT5-1 material

GOST -19807 - 91

| Fe | C | Si | V | N | You | Al | Zr | O | Sn | H | Impurities |

|---|---|---|---|---|---|---|---|---|---|---|---|

| up to 0.3 | up to 0.1 | up to 0.12 | up to 1 | up to 0.05 | 88.83 - 93.4 | 4.3 - 6 | up to 0.3 | up to 0.15 | 2 - 3 | up to 0.015 | other 0.3 |

Note: Ti is the basis; Ti percentage is approximate.

Technological properties of the BT5-1 material.

| Weldability: | without restrictions. |

Mechanical properties at T=20 o C of BT5-1 material.

| Assortment | Size | For example. | σin | σT | δ5 | ψ | KCU | Thermal processing |

|---|---|---|---|---|---|---|---|---|

| - | mm | - | MPa | MPa | % | % | kJ/m² | - |

| Annealed sheet, GOST 22178-76 | 735 | 8-15 | ||||||

| Annealed rod, GOST 26492-85 | 745-785 | 6-8 | 15-20 | 400 | Annealing | |||

| Rod, high quality, GOST 26492-85 | 745-980 | 6-10 | 18-25 | 400-450 | Annealing | |||

| Plate, GOST 23755-79 | 11 - 35 | 735-930 | 6 | 12 |

| Hardness VT5-1, | HB 10-1 = 269 - 363 MPa |

Physical properties of the material BT5-1.

| T | E 10-5 | α 106 | λ | ρ | C | R 109 |

|---|---|---|---|---|---|---|

| Haill | MPa | 1/Grad | W/(m deg) | kg/ m3 | J/(kg deg) | Ohm m |

| 20 | 1.1 | 4425 | 0.502 | 1380 | ||

| 100 | 8.3 | 0.544 | ||||

| 200 | 9.3 | 10.88 | 0.565 | |||

| 300 | 9.7 | 12.14 | 0.586 | |||

| 400 | 10 | 13.14 | 0.628 | |||

| 500 | 10.3 | 14.65 | 0.67 | |||

| 600 | 10.4 | 15.91 |

Foreign analogues of the material VT5-1

Attention! Both exact and closest analogues are indicated.

| USA | Germany | Japan | France | England |

|---|---|---|---|---|

| - | DIN, WNr | JIS | AFNOR | B.S. |

| 5Al-2.5Sn Grade6 | 3.7114 3.7115 | KS-5-2.5 SAT-525 | Ti-P.65 | IMI317 |

Applications of BT5-1 Titanium Alloy

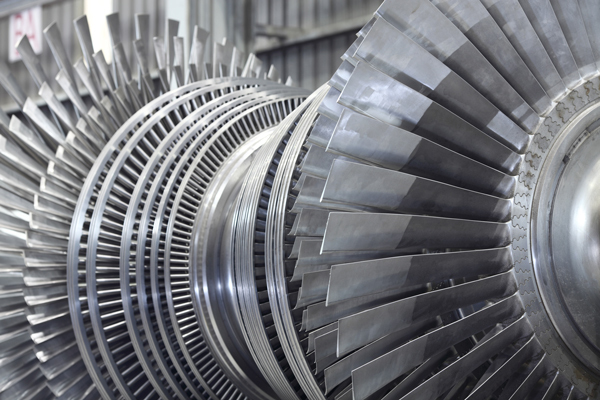

Aerospace Structures

Gas turbine components, engine casings, and other high-performance aerospace parts.

Chemical Processing

Equipment for handling corrosive materials at high temperatures.

Automotive

High-performance automotive parts exposed to extreme heat and stress.

Marine

Components used in shipbuilding and other marine applications requiring high strength and corrosion resistance.

BT5-1 Titanium Round Bars and Custom Products

At Russian Metals, we supply BT5-1 titanium round bars, sheets, and custom shapes for a variety of industries. Our BT5-1 titanium products are ideal for precision-engineered components that demand superior strength, corrosion resistance, and reliability. Available in various sizes, our titanium products are sourced from certified manufacturers and undergo stringent quality checks to ensure they meet international standards.

Why Choose Russian Metals for BT5-1 Titanium?

High-Quality Products

We supply only certified BT5-1 titanium alloys, ensuring superior strength, performance, and reliability.

Timely Delivery

We provide fast, nationwide delivery in India, with a robust supply chain that ensures timely availability of all sizes and forms.

Customization Options

Our BT5-1 titanium alloy products can be tailored to your specific requirements, whether it’s for aerospace components or custom industrial machinery parts.

Competitive Pricing

We offer premium BT5-1 titanium alloys at competitive rates, ensuring value for money without compromising quality.

Get in touch with Russian Metals today to order BT5-1 titanium alloy for your aerospace and industrial applications. We offer BT5-1 titanium round bars, sheets, and custom products to meet your specific needs with reliable customer service and fast delivery.

Contact Us for BT5-1 Titanium Orders

For more information or to place an order, contact Russian Metals today. We specialize in providing the best quality GOST BT5-1 Titanium at competitive prices for industrial, defense, and aerospace applications.