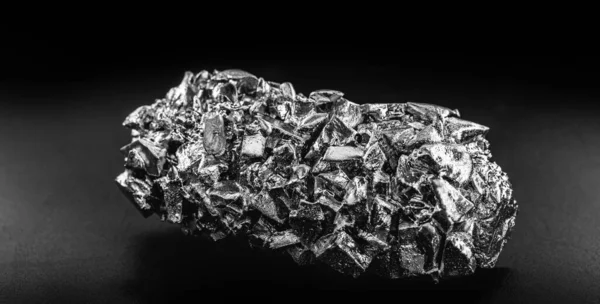

OT4-0 (OT4-0)

OT4-0 Titanium Alloy: Ideal Material for Chemical Processing Equipment

OT4-0 titanium is a wrought titanium alloy widely used in chemical processing equipment due to its outstanding corrosion resistance, high strength, and thermal stability. At Russian Metals, we specialize in providing OT4-0 titanium in various forms such as sheets, rods, and bars. Whether for aerospace structures, chemical plants, or other heavy-duty applications, OT4-0 offers unparalleled performance under extreme conditions.

What is OT4-0 Titanium Alloy?

OT4-0 TITanium is a high-performance titanium alloy that boasts excellent strength-to-weight ratio, making it suitable for demanding industrial applications. The alloy's ability to resist corrosion in aggressive chemical environments and its ability to withstand high temperatures make it perfect for chemical processing and aerospace industries.

At Russian Metals, we offer this aerospace-grade OT4-0 titanium with precise specifications to meet the needs of our clients.

OT4-0 exhibits good thermal stability, allowing it to maintain its mechanical properties at elevated temperatures. It can operate at temperatures up to 350°C for extended periods without significant degradation. This makes it suitable for components exposed to moderate heat environments.

Characteristics of the material OT4-0

| Grade : | OT4-0 |

| Classification : | Titanium wrought alloy |

| Application: | parts of complex configuration, operating for a long time at a temperature of 300-350°C and for a short time at a temperature of 500-600°C; good corrosion resistance; pseudo α structure class |

| Foreign analogues: | No Data |

Chemical composition in % of OT4-0 material

GOST -19807 - 91

| Fe | C | Si | Mn | N | You | Al | Zr | O | H | Impurities |

|---|---|---|---|---|---|---|---|---|---|---|

| up to 0.3 | up to 0.1 | up to 0.12 | 0.5 - 1.3 | up to 0.05 | 96.13 - 98.8 | 0.4 - 1.4 | up to 0.3 | up to 0.15 | up to 0.012 | other 0.3 |

Note: Ti is the basis; Ti percentage is approximate.

Technological properties of the OT4-0 material.

| Weldability: | without restrictions. |

Mechanical properties at T=20 o C of material OT4-0.

| Assortment | Size | For example. | σin | σT | δ5 | ψ | KCU | Thermal processing |

|---|---|---|---|---|---|---|---|---|

| - | mm | - | MPa | MPa | % | % | kJ/m² | - |

| Annealed sheet, GOST 22178-76 | 470 | 20-30 | ||||||

| Pipes, GOST 24890-81 | 490-637 | 15 | ||||||

| Rod, GOST 26492-85 | 440 | 13-15 | 30-35 | 400-500 | Annealing | |||

| Rod, high quality, GOST 26492-85 | 440-635 | 20 | 32-40 | 500-700 | Annealing |

| Hardness OT4-0, Sheet | HB 10-1 = 200 MPa |

| Hardness OT4-0, Rod | HB 10-1 = 156 - 207 MPa |

Physical properties of the material OT4-0.

| T | E 10-5 | α 106 | λ | ρ | C | R 109 |

|---|---|---|---|---|---|---|

| Haill | MPa | 1/Grad | W/(m deg) | kg/ m3 | J/(kg deg) | Ohm m |

| 20 | 1.15 | 4514 |

Applications of OT4-0 Titanium Alloy

OT4-0 titanium is a versatile alloy used in several high-performance applications, especially in chemical processing equipment and aerospace structures.

Key Applications:

Chemical Processing Equipment

OT4-0's corrosion resistance makes it ideal for use in harsh chemical environments, such as chemical plants, pipes, and reactors.

Aerospace Structures

OT4-0 titanium is used in aerospace applications, including aircraft structural components, where high strength and lightweight properties are essential.

Marine and Offshore Equipment

The alloy’s resilience to saltwater corrosion makes it an excellent choice for marine structures.

Heat Exchangers and Pumps

OT4-0 titanium is used in heat exchangers, valves, and pumps where thermal resistance and strength are required.

Why Choose Russian Metals for OT4-0 Titanium?

At Russian Metals, we are a leading supplier of OT4-0 titanium and affordable OT4-0 titanium alloy products for chemical processing and aerospace industries. Here's why you should choose us:

Key Benefits:

High-Quality Materials

We provide premium OT4-0 titanium alloy that meets the highest standards of quality and performance.

Affordable Pricing

We offer OT4-0 alloy cost estimates that are competitive and provide value for your investment.

Wide Range of Products

We offer OT4-0 titanium sheets, rods, and bars in various sizes and specifications.

Expert Support

Our team provides technical guidance to help you select the right OT4-0 titanium alloy for your needs.

Fast Delivery

We ensure reliable and timely delivery across India, meeting the demands of chemical processing plants and aerospace manufacturers.

Get a Quote for OT4-0 Titanium Alloy Today

If you're in need of OT4-0 titanium alloy for chemical processing equipment or aerospace structures, Russian Metals is here to help. Contact us today to get a cost estimate and to learn more about our affordable OT4-0 titanium alloy options. Our expert team is ready to assist you with your material needs and provide customized solutions.