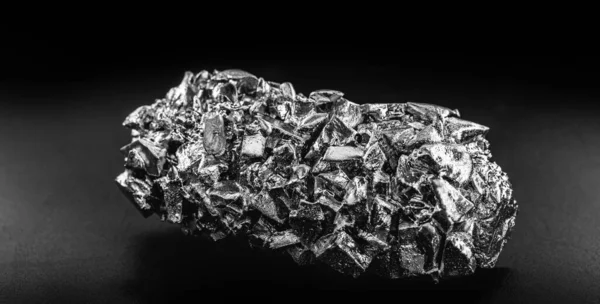

SPT-2 (СПТ-2)

SPT-2 Titanium: The Alloy of Choice for High-Performance Applications

SPT-2 Titanium a high-strength titanium alloy primarily used in industrial applications that demand both superior strength and resistance to corrosion. At Russian Steels, we provide SPT-2 titanium in various forms, including wire, sheet, and plate, to meet the diverse needs of aerospace, chemical, and marine industries. SPT-2 is a Russian titanium alloy (GOST 27.265-87) primarily used for welding wire and structural components. It is an α + β alloy containing about 3.5–4.5% aluminum, 2.5–3.5% vanadium, and 1–2% zirconium, with titanium as the base element. The alloy offers moderate strength (≈ 645–845 MPa), good ductility (≥ 13%), and excellent weldability.

What is SPT-2 Titanium?

SPT-2 titanium stands for Service Parallel Thermoplastic 2, and it’s one of the most reliable titanium alloys available. Combining titanium, aluminum, and vanadium, SPT-2 offers excellent strength-to-weight ratio, along with corrosion resistance and good weldability. These characteristics make it ideal for harsh environments, including applications that require resistance to both abrasion and corrosion.

Its density is ~4.5 g/cm³ and elastic modulus ~112 GPa, giving a good balance of strength-to-weight ratio. SPT-2 is valued for its stable mechanical performance, corrosion resistance, and reliability in welded joints, making it ideal for aerospace, chemical, and marine applications, especially where durable and lightweight welding materials are required.

Characteristics of the material SPT-2

| Brand : | SPT-2 |

| Classification : | Titanium wrought alloy |

| Application: | for the production of welding wire |

| Foreign analogues: | No data |

Chemical composition in % of SPT-2 material

GOST -27265 - 87

| Fe | C | Si | V | N | You | Al | Zr | O | H | Impurities |

|---|---|---|---|---|---|---|---|---|---|---|

| up to 0.15 | up to 0.05 | up to 0.1 | 2.5 - 3.5 | up to 0.04 | 89.36 - 92.7 | 3.5 - 4.5 | 1 - 2 | up to 0.12 | up to 0.003 | other 0.3 |

Note: Ti is the basis; Ti percentage is approximate.

Mechanical properties at T=20 o C of material SPT-2.

| Assortment | Size | For example. | σin | σT | δ5 | ψ | KCU | Thermal processing |

|---|---|---|---|---|---|---|---|---|

| - | mm | - | MPa | MPa | % | % | kJ/m² | - |

| Wire, GOST 27265-87 | 645-845 | 13 |

Physical Properties of material SPT-2.

| Symbol | Property | Unit |

|---|---|---|

| T | Test temperature | Grade |

| E | Young modulus | MPa |

| α | Coefficient of linear expansion (20° - T) | 1/Grade |

| λ | Thermal (heat) condition coefficient | Watt/(m·Grade) |

| ρ | Density | kg/m³ |

| C | Specific heat (range 20° - T) | J/(kg·Grade) |

| R | Electrical resistance | Ohm·m |

Key Features of SPT-2 Titanium

- Tensile Strength: SPT-2 Titanium offers an impressive tensile strength of 130–134 ksi (896–924 MPa), providing excellent resistance to deformation and ensuring the material's reliability in high-stress applications like aerospace and marine industries.

- Corrosion Resistance: SPT-2 Titanium exhibits outstanding corrosion resistance, particularly in saltwater, acidic substances, and other harsh conditions. This makes it the material of choice for industries like chemical processing, offshore engineering, and marine applications, where durability in aggressive environments is critical.

- Weldability: SPT-2 Titanium offers high weldability, enabling the creation of complex structures without compromising its mechanical properties. This feature makes it highly suitable for applications in aerospace, industrial machinery, and other sectors requiring intricate welded components.

- Fatigue Resistance: SPT-2 Titanium is highly resistant to fatigue, making it an ideal choice for components exposed to cyclic loading. This property ensures long-term performance in industries like aerospace and automotive where parts undergo repeated stress.

- Low Thermal Expansion: SPT-2 Titanium has a low coefficient of thermal expansion, making it perfect for applications that require dimensional stability under fluctuating temperatures, such as in precision engineering and high-temperature systems.

- Lightweight: Despite its high strength, SPT-2 Titanium remains lightweight, making it an excellent option for aerospace and marine applications where weight reduction is crucial for fuel efficiency, safety, and overall performance.

Difference Between SPT1 and SPT2

While both SPT1 and SPT2 are used for electrical wiring, SPT-2 offers superior characteristics compared to SPT-1. Below is a comparison between the two:

SPT-1 Characteristics

- Insulation Thickness: 0.03 inches

- Usage: Primarily for light-duty applications, such as household appliances and lamp cords.

SPT-2 Characteristics

- Insulation Thickness: 0.045 inches

- Usage: Ideal for medium-duty applications such as power tools and kitchen appliances.

Key Differences

- Insulation Thickness: SPT-2 has thicker insulation than SPT-1, offering greater protection.

- Durability: SPT-2 is more durable and suited for longer-term use in moderate environmental conditions, while SPT-1 is typically used for short-term or indoor applications.

SPT-2 Wire Specifications

SPT-2 Wire Mechanical Properties

- Tensile Strength: 130–134 ksi (896–924 MPa)

- Yield Strength: 120–126 ksi (827–869 MPa)

- Elongation: 8–10%

- Hardness: 45–60 HB

SPT-2 Wire Construction

- Material: Titanium alloy with aluminum and vanadium.

- Dimensions: Available in various gauges such as 18 and 16, suitable for a wide range of electrical applications.

SPT-2 Wire Insulation

- Insulation Thickness: 0.045 inches

- Material: PVC (Polyvinyl Chloride), which is thicker and more durable compared to SPT-1.

Applications of SPT-2 Titanium

SPT-2 Titanium is used in various demanding sectors:

Aerospace Applications

In aerospace, SPT-2 titanium is used in aircraft components, turbine blades, and engine parts, where high strength and lightweight properties are essential.

Marine Industry

SPT-2 titanium is widely used in marine vessels, heat exchangers, and other marine infrastructure due to its resistance to saltwater corrosion.

Industrial Applications

From power generation to chemical processing, SPT-2 titanium is used for heat exchangers, tubing, and piping that need to withstand extreme environments.

Why Choose Russian Steels for SPT-2 Titanium?

At Russian Steels, we offer the highest quality SPT-2 titanium products that meet rigorous industry standards. Here’s why we’re your go-to supplier:

- Premium Quality: We source only premium-grade SPT-2 titanium.

- Variety of Forms: We provide SPT-2 wire, sheet, plate, and bar for diverse industrial uses.

- Competitive Pricing: As a direct titanium supplier, we offer competitive pricing without compromising on quality.

- Expert Support: Our team provides technical support and product guidance for your specific needs.

Contact Russian Steels for SPT-2 Titanium

If you’re looking for high-quality SPT-2 titanium, look no further than Russian Metals. Whether you need SPT-2 wire or sheet for industrial, marine, or aerospace applications, we’ve got you covered. Reach out today for customized solutions and reliable delivery.